Chuck Table

Product Details:

- Product Type Chuck Table

- Material Metal (Cast Iron/Steel)

X

Chuck Table Price And Quantity

- 1 Set

- ±0.005 mm

- Mechanical or electrical

- Varies as per size

- Up to 250 mm (custom sizes available)

- Precision ground

- High

- ±0.01 mm

- Flange or direct mounting

- Milling, Drilling, Grinding machines

- Manual or Power

Chuck Table Product Specifications

- Chuck Table

- Metal (Cast Iron/Steel)

- ±0.005 mm

- Mechanical or electrical

- Varies as per size

- Up to 250 mm (custom sizes available)

- Precision ground

- High

- ±0.01 mm

- Flange or direct mounting

- Milling, Drilling, Grinding machines

- Manual or Power

Chuck Table Trade Information

- TAIWAN

- 2-5 Set Per Month

- 12 Week

- Carton Packing Wooden Box Packing

- D-U-N-S65-868-8684 by TUV Rheinland

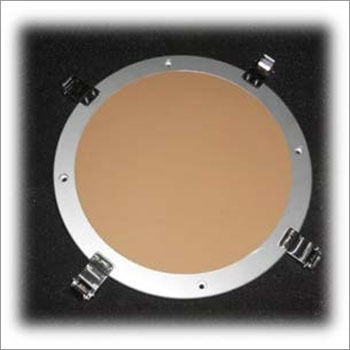

Product Description

With the help of our specific and brilliantly controlled synthesis process, the permeable ceramic panel or substrate has uniform distribution of pores and uniform size. Completely distributed effect can be achieved by using it in the field of object suction or filtration.

Principal characteristics of Chuck Table:

- Automatic load-unload

- Chuck table for IC and LED wafer ,glass dicing ,etc

- Filtration

- Fixed position

- High precision screen printing

- High precision stacking

- Object suction

- The size of the pore can be controlled in the array from sub micrometer to several tenth micrometers

Engineered for Precision and Versatility

The Chuck Table stands out with its finely ground surface and strict dimensional tolerances, making it optimal for high-accuracy industrial machining. Its flexible mounting options and tailored designs ensure seamless integration into milling, drilling, and grinding machines across different sectors.

Enhanced Durability for Demanding Environments

Made from premium cast iron or steel, the Chuck Table exhibits remarkable resistance to wear and corrosion. This ensures reliable performance and longevity even under continuous and intensive use, reducing maintenance requirements and downtime for manufacturers.

FAQs of Chuck Table:

Q: How is the Chuck Table typically mounted onto a machine?

A: The Chuck Table can be mounted using either a flange or direct mounting method, allowing for compatibility with a range of milling, drilling, and grinding machines.Q: What are the key benefits of using a precision ground surface table in machining?

A: A precision ground surface ensures accurate workpiece positioning and reliable clamping, leading to enhanced parallelism and concentricity critical for top-quality machining results.Q: When should I choose manual clamping versus power clamping for this table?

A: Manual clamping is suited for operations requiring simple and frequent adjustments, whereas power clamping provides efficiency in high-volume or repetitive settings, supporting streamlined workflows.Q: Where are these Chuck Tables manufactured and exported from?

A: These Chuck Tables are designed, manufactured, and exported by leading suppliers in Taiwan, renowned for high-quality engineering and export standards.Q: What is the recommended process for selecting the right Chuck Table diameter?

A: Select the diameter based on your applications workpiece size and machine compatibility; custom sizes are also available to accommodate special requirements.Q: How does the high corrosion resistance benefit the operational lifespan of the Chuck Table?

A: The high corrosion resistance, achieved through material choice and surface treatment, significantly extends the tables life in harsh machining environments, ensuring consistent reliability and reducing maintenance needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Chuck Table' category

|

CEPHEUS TECHNOLOGY LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry