Aluminum Chuck Table

Product Details:

- Product Type Aluminum Chuck Table

- Material High-Grade Aluminum Alloy

X

Aluminum Chuck Table Price And Quantity

- 1 Set

Aluminum Chuck Table Product Specifications

- High-Grade Aluminum Alloy

- Aluminum Chuck Table

Aluminum Chuck Table Trade Information

- TAIWAN

- 2-5 Set Per Month

- 12 Week

- Carton Packing Wooden Box Packing

- All India

- D-U-N-S65-868-8684 by TUV Rheinland

Product Description

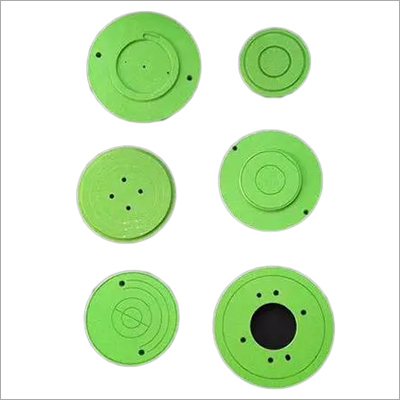

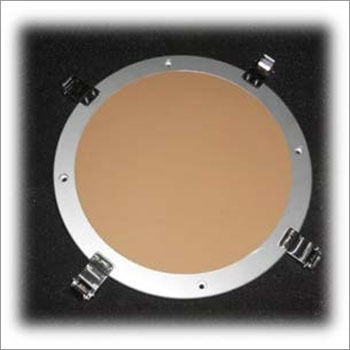

Customized design and surface Teflon coating chucktable.

- Model: Aluminum vacuum suction cup

- description: Customized design, non-sticky surface treatment

Features:

- The pore size can be from sub-micron to tens of microns.

- The material is hard and the breaking stress can reach 9001000 kg/cm2.

- Flatness can reach 5 um/100 mm.

Its size can be: 2 inches, 3 inches, 4 inches, 5 inches, 6 inches, 8 inches, 12 inches... and other specifications, and can be produced in various sizes within 300mm.

Precision and Reliability

Engineered for applications requiring extreme accuracy, our Aluminum Chuck Table boasts a flatness tolerance of 0.02 mm and robust T6 hardness. Its anodized surface finish ensures both corrosion resistance and long-lasting performance, making it an ideal choice for demanding CNC and semiconductor environments.

Customizable for Your Needs

Available in various thicknesses (20-50 mm) and with custom-drilled mounting holes, each table is built to your specific requirements. From accommodating unique clamping setups to supporting heavy loads up to 200 kg, our team in Taiwan works closely with you for optimal integration.

FAQs of Aluminum Chuck Table:

Q: How is the Aluminum Chuck Table surface treated to ensure corrosion resistance?

A: The surface of the Aluminum Chuck Table is anodized, which enhances corrosion resistance and delivers a durable, silver finish. This treatment is particularly beneficial for applications in environments where exposure to coolants or chemicals is common.Q: What applications is this Aluminum Chuck Table best suited for?

A: This table is specifically designed for precision clamping, making it ideal for CNC machines, semiconductor equipment, and other high-precision manufacturing processes that demand accuracy and stability.Q: When should I consider customizing the thickness and mounting holes of the table?

A: Customizing the thickness (from 20 to 50 mm) and mounting holes is recommended when your application requires specific support capacity, integration with specialized equipment, or unique fixturing arrangements for efficient operation.Q: Where is this Aluminum Chuck Table manufactured and supplied from?

A: Our Aluminum Chuck Tables are manufactured and exported directly from our advanced facility in Taiwan, ensuring strict quality control and reliable global supply.Q: What process is followed to achieve the T6 hardness and flatness tolerance?

A: The table is constructed from high-grade aluminum alloy and undergoes T6 heat treatment, which enhances hardness. Precision machining methods are then employed to achieve a flatness tolerance within 0.02 mm.Q: How does using this product benefit CNC and semiconductor manufacturers?

A: By providing exceptional flatness, customizable mounting, and strong load capacity, the table ensures stable clamping and precise positioning, ultimately improving the accuracy, efficiency, and quality of manufacturing processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Chuck Table' category

|

CEPHEUS TECHNOLOGY LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry